Krytox Performance lubricants Characteristics

Chemours Krytox Performance Lubricants Characteristics – Part II

Extreme Temperature Performance

- Krytox oils and greases are the product of choice in extreme temperature conditions. Most petroleum products begin to degrade above 99 °C (210 °F) and are too viscous at temperatures just below –18 °C (0 °F).

- Krytox synthetic lubricants have extreme temperature stability, with operating ranges from below –75 °C up to 350 °C (–103 °F to 662 °F) and temperatures up to 400 °C (752 °F) with appropriate metallurgy. Under the D-3336 test conditions of 177 °C (350 °F) and 10,000 rpm, the majority of competing hydrocarbon lubricants fail in less than 1,000 hr.

- But the general purpose line of Krytox lubricants has been shown to last over 5,000 hr without failure, even at an increased temperature of 200 °C (392 °F). This extreme condition performance is what distinguishes Krytox performance lubricants from other competing products.

Cost Effective of Krytox Performance lubricants

- Krytox lubricants are cost effective across a wide range of applications. Due to their inert nature, Krytox lubricants provide a much longer usable life as compared to typical hydrocarbon oils and greases, and the longer usable life allows them to remain for considerable periods of time before needing to be replaced, if they are replaced at all.

- That translates to savings over time, both by lowering the amount of lubricant purchased and any downtime incurred during relubrication.

Performance Additives of Krytox Performance lubricants

- Anti-corrosion additives are combined with Krytox grease to enhance its ability to protect metallic surfaces from corrosion caused by moisture and oxygen.

- Chemours also offers a patented oil-soluble additive to give the same corrosion protection to our oils.

- Krytox greases containing anti-wear additives have properties that give high specific load-carrying capacity and the highest protection against wear.

Compatibility with Elastomers and Plastics

- Krytox base oil is compatible with all elastomeric seal materials and engineering plastics. The limiting factor when using standard1 Krytox with any material is the thermal stability of the elastomer or plastic.

- Krytox performance lubricants are compatible with most common elastomers and plastics including:

| ABS

Acetal — homopolymer and copolymer Aramids Buna N Butyl 325 Chlorosulfonated polyethylene Delrin acetal EPDM EPT, peroxide cure Ethylacrylate FEP Fluoroelastomers Fluorosilicone HDPE HNBR Hydrocarbon rubber Hypalon synthetic rubber Hytrel polyester elastomer Kalrez fluoroelastomer2 LDPE Methyl silicone Natural rubber NBR Neoprene WRT Nitrile Nylon Nylon 6 Nylon 6,6 Nylon 12 |

PEBA

PEEK Polyamides Polycarbonate Polyetheramide block copolymer Polyethylene Polypropylene PTFE fluorocarbon PVC SBR SEBS Silicone Styrene ethylene butylene polymer Styrenic polymer Teflon fluorocarbon Thermoplastic polyurethane Thermoset polymers Thermoplastic rubber TPE TPU Urethane Vamac ethylene acrylic elastomers Vespel polyimide resin Viton fluoroelastomers Zytel nylon |

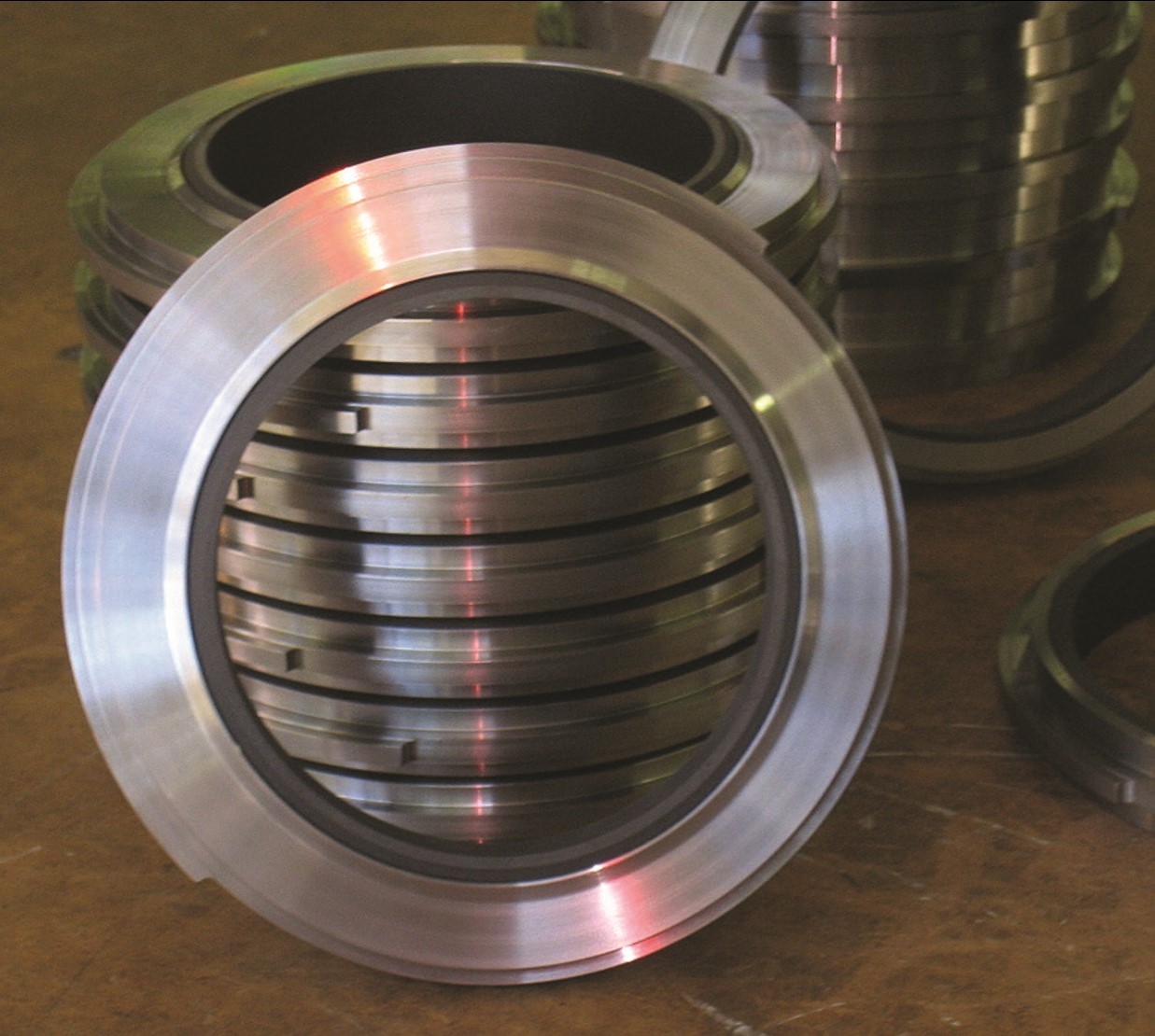

Extreme Pressure (EP)

- Chemours Krytox heavy-duty greases are used for high loading or slow speeds. EP greases have high load-carrying capability and good lubrication characteristics under boundary and mixed friction conditions.

- In addition to the EP additive in Krytox heavyduty greases, Krytox oil provides adequate EP protection as an oil by itself, due to the viscosity build under load and its unique tribo-chemistry.

“Liked this post? Subscribe to our newsletter and get loads more!”